what are the models to determine the optimum level inventory

February 22, 2021

Maintaining an optimal stock level in the warehouse is essential for having efficient logistics systems and avoiding actress storage costs. But what's the exact number of SKUs you need for to finer run into product need without suffering from stockouts?

In this postal service, we take an in-depth expect at optimal stock levels in logistics besides equally the differences betwixt this concept and minimum and safety stock levels. Plus, nosotros break down the formula for making sure your inventory is in line with demand, the installation, and the steady growth of your visitor.

Optimal stock: what is it and how do you put it in exercise?

In logistics, optimal stock designates the exact amount of inventory a business organisation requires to fulfill routine need without the occurrence of a stockout. In other words, information technology involves obtaining maximum profitability and bringing storage costs down to a minimum.

This concept shouldn't be confused with average stock (or average inventory), which is the average number of SKUs in the warehouse. This number oscillates betwixt the maximum stock level — which refers to the total items able to be stored in the installation taking into account the square footage and storage systems employed — and the reorder point or minimum inventory level, which defines the limit at which the company needs to procure more product.

Ignoring the optimal stock level could lead to serious consequences for the warehouse

How to decide optimal stock levels

Which factors should the logistics manager consider to determine the optimal stock level? Although this depends on each firm's particular strategy, these are the four main elements to conduct in heed:

- Client need. The logistics manager, together with the accounting section and direction, should clarify need trends over the years, the demand forecast for each SKU, seasonal need for each product, etc.

- Stock turnover. The manager needs to know the turnover for each SKU to properly manage goods slotting. The ABC assay is a common method for organizing SKUs according to their demand.

- Product blazon. The characteristics of each product, as well as the company's business concern sector, will exist primal when information technology comes to assessing optimal stock levels based on the storage systems installed. For instance, nutrient logistics, which calls for cold storage lest the goods expire, differs profoundly from the warehousing of cables and pipes, whose products require specific storage systems that adapt to their characteristics.

- Maximum, minimum, and safety stock levels. With these three numeric values, you can calculate the optimal stock level for each SKU. Thus, the space, methodology, storage systems, and handling equipment will determine the maximum stock level, while the demand and capacity to manage each gild will found the minimum level. For its function, the nature of the business organization will designate the necessary safety stock in each installation.

- Lead time. The warehouse director as well has to know the lead time for each supplier. That is, the time elapsed from the moment a stock entry order is generated in the warehouse until the supplier delivers the product.

Against a logistics backdrop in which efficiency and the reduction of storage costs are increasingly important, ignoring optimal stock levels could result in major repercussions for the company. These might include inefficient storage processes, expensive overstock, and, above all, spoilage of warehouse stock, especially if this includes perishable goods.

Stock types: optimal, minimal, and safety

It'southward impossible to understand optimal stock without kickoff running through other concepts, such as working stock, safety stock, and the reorder point. Let'due south examine the different types of stock co-ordinate to logistics strategy:

- Available stock: this refers to the amount of stock in the warehouse that's ready to be included in any order. All logistics processes are carried out on the basis of available stock, also known as working stock.

- Minimum stock: this is the minimum amount of each product the warehouse must have to respond to demand.

- Condom stock: every installation should have safety stock (sometimes called buffer stock) in order to prevent stockouts in the upshot of an unexpected rise in demand.

- Order point: numeric value established in the logistics strategy that determines when an order should exist placed with a supplier. Information technology lies between the minimum and optimal stock levels.

- Maximum stock: this concerns the amount of stock that must not be exceeded in guild to continue warehouse operations running smoothly. It's related to the installation'due south storage capacity and the concern's workforce.

Now that we're clear on these concepts, we tin calculate the optimal stock level. As mentioned earlier, this refers to the amount of inventory to maintain to ensure that the company obtains maximum profitability and can answer to both existing need and any fluctuations that may occur.

Optimal stock level formula

Once the logistics manager has taken into account the considerations set out in the point above, he/she should employ the optimal stock level calculation to know exactly how much of each item to store in the warehouse. To obtain this datum, we take the optimal order quantity and add to it the minimum stock and safety stock that should be on hand in the installation. This is how we go these variables:

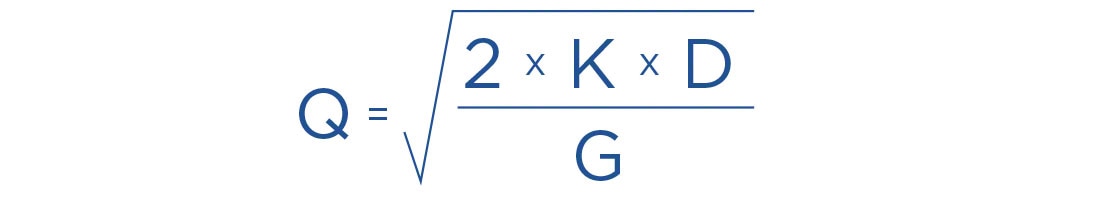

The optimal order quantity is related to the Wilson model, which uses the amount and frequency with which orders are placed with suppliers to reach optimal direction of inventory and of raw material procurement. The formula beneath is used to calculate this numeric value:

The optimal stock level formula is based on the Wilson model

Where Q is the optimal gild quantity, D is the annual demand for raw material, Grand is the cost of each order, and Thousand is the price of storing a product for a specific amount of fourth dimension. As a issue, thanks to the Wilson model, the warehouse manager volition know when an society should exist placed.

Besides the optimal gild quantity, we need to obtain the installation'due south minimum and rubber stock levels. This formula determines a warehouse's minimum stock level:

Minimum stock level formula

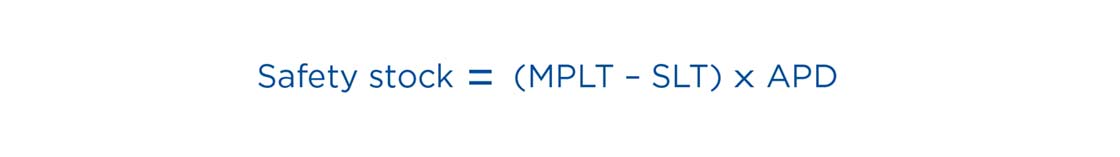

To this calculation, we need to add the safety stock calculation, which is adamant using the following variables:

- Supplier lead time nether normal circumstances (SLT).

- Maximum procurement pb time in the event of an incident (MPLT).

- Boilerplate production demand (APD).

Safety stock formula

Finally, the optimal stock level formula would be worked out as follows:

Optimal stock level = optimal order quantity + minimum stock level + safety stock level

Example of how to calculate optimal inventory level

Permit's illustrate the formulas higher up with a specific example. A steel company has a raw materials warehouse that supplies its production heart with bolts. The company requires 80,000 bolts a year to manufacture the metal sheeting it sells.

Each order the firm places with its bolt supplier costs $100, while the cost of storing a bolt is nearly $0.05 annually. So what's the optimal stock level of bolts the company should take in its installations?

Every bit seen above, the first pace is to summate the optimal order quantity. Using the formula, where K (the cost of the order) is $100, D (the annual demand) is lxxx,000 bolts, and G (the unit of measurement cost of storing a bolt) is $0.05, nosotros obtain a Q of 17,888 bolts.

Q or optimal order quantity = √((2 × 100 × 80,000) / 0.05) = 17,888 bolts

Subsequently, to summate the optimal stock level, we have to determine the minimum amount of stock there should be in the warehouse. To do this, it'south necessary to figure out how many bolts the company requires per unit of measurement of fourth dimension (per twenty-four hour period). If the company operates 250 days a year, it will demand 320 daily units. Consequently, if the supplier's pb time is just a week, the minimum stock needed volition be 2,240 units.

Minimum stock = (80,000/250) × 7 = 320 × 7 = 2,240 bolts

To end upwardly, nosotros'll calculate the amount of safety stock the warehouse should have. If the supplier's maximum atomic number 82 fourth dimension under abnormal conditions is 21 days, the conclusion is that the safety stock should be 4,480 units.

Safe stock = (21 − vii) × 320 = 4,480 bolts

Therefore, the optimal stock calculation is 24,608 bolts: the issue of calculation the optimal lodge quantity (17,888), the minimum stock (2,240), and the safety stock (iv,480).

Optimal stock level = 17,888 + 2,240 + 4,480 = 24,608 bolts

WMSs automatically organize tasks such as picking and stock replenishment

Digitization of optimal stock levels

The digitization of logistics processes has fabricated it possible to automate multiple tasks that used to lead to mistakes and crusade operators to lose valuable time. The implementation of an ERP (enterprise resources planning) organization is key for integrating order management in the warehouse and knowing the demand for each product and the lead fourth dimension of each provider, among other data. In the end, it helps the logistics manager to calculate optimal stock levels and the optimal order book for each supplier.

Once you've determined the optimal stock levels for each SKU, a warehouse management organization (WMS) can automatically prioritize processes such equally replenishment at the pick stations, the receipt of inbound orders, and fifty-fifty management of the product lines at the installation.

Moreover, these applications calculate the optimal stock levels for each SKU, which will automatically generate replenishment tasks for products beneath the preset limit. As for warehouse slotting, a WMS automatically assigns each product a location based on its attributes (turnover, batch, and expiration date), minimizing errors and boosting productivity in the installation.

Accurateness and flexibility: the crux of Logistics 4.0

With logistics and industry condign more than and more than demanding, logistics managers are forced to cut costs in storage and order prep processes to be more competitive. For this reason, using tools such as optimal stock levels eliminates errors and overcosts, guaranteeing enough inventory to satisfy the demand for each SKU without incurring unnecessary costs.

Notwithstanding, a growing number of logistics managers are implementing solutions to automate stock flows. One time you've calculated the optimal stock level, a WMS, together with an ERP system, enables you to schedule orders to suppliers and sequence replenishment tasks, in add-on to a host of other avant-garde features.

At Interlake Mecalux, we offer Like shooting fish in a barrel WMS, a WMS with multiple applications in the logistics sector. If you lot're interested in ramping upwardly the efficiency of your business organization'south processes and optimally monitoring stock, be sure to get in affect. 1 of our skilful consultants will suggest you on the best digital solution for your company.

Source: https://www.interlakemecalux.com/blog/optimal-stock-level

0 Response to "what are the models to determine the optimum level inventory"

Enregistrer un commentaire